Our Strengths

- Ability to deliver products to end customer in various states

- Customer Satisfaction – 98 %

- Quality Performance – 99 %

- Delivery Performance – 99 %

Procedures We Follow

- Procedures We Follow

- Kaizen Technique – Small Continual Improvements

- 5 S Technique

- Use of Poka-Yoke – Lean Manufacturing

- ProcessMapping – Identify, Reduce or Eliminate NVA’s

- Root Cause Analysis

- Training and Qualification for Critical Processes

- Visuals to Monitor and Review the Results

- Initiatives to Improve Work Environment and Safety (EHS)

Ensuring Product Quality

- Controlling quality of inputs

- Monitoring supplier quality and delivery performances

- Monitoring quality during production by checking

- In process Rework

- In process Rejection

- Internal Quality Assurance Plan

- Process Flow Diagrams at Shop floors

- Standard Operating Procedures

Welding Competencies

Welding Process Qualified as per ASME Section IX – GMAW, GTAW, SMAW

Welding Process Qualified as per PED – GTAW, Welding Inspector as per ASME, Section IX

Welding Inspector as per ASME, EM Section IX

Visual Testing

Liquid Penetration Testing

Blasting Competencies

Surface Preparation as per SA 2 1/2

Separate Blasting Booth

Blasting Inspection Gauges

Painting Competencies

Painters Qualified as per ASTM – D 4228-05 (2012)

Separate Paint Booths

Air Pressure and Airless Spray Painting Equipment

Painting Inspection Gauges

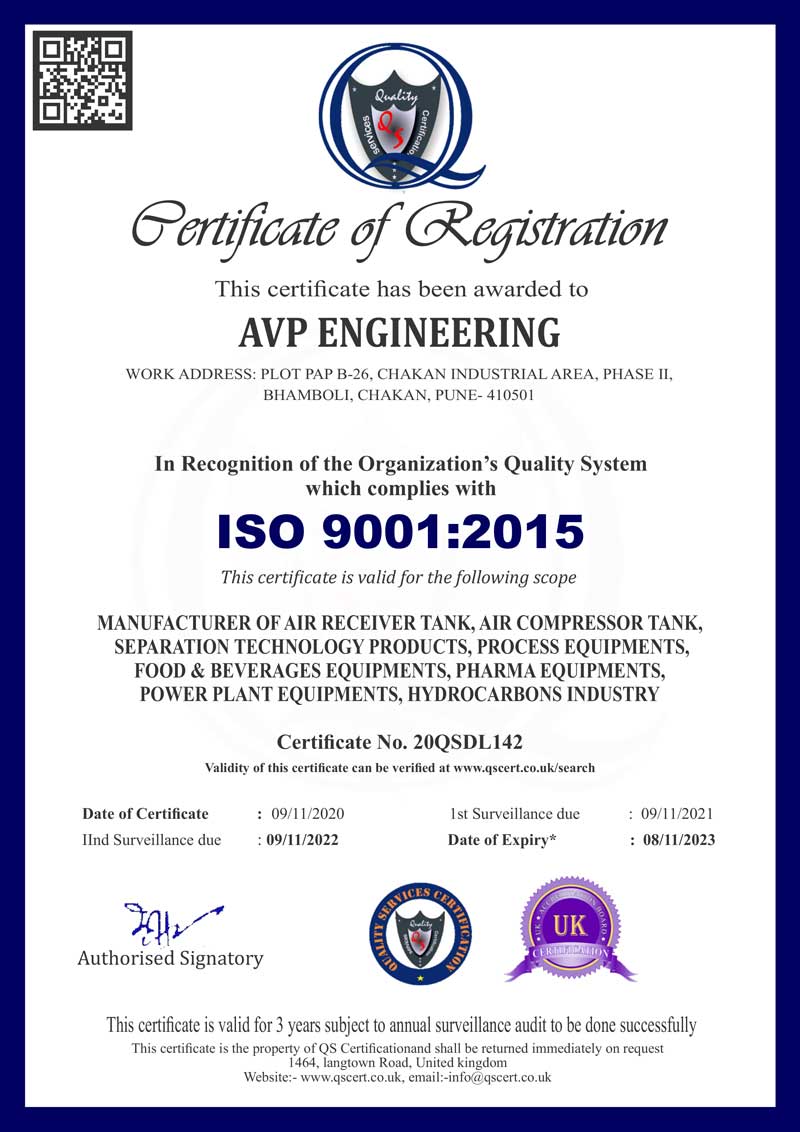

Our Certifications

Quality Policy

We, at AVP Engineering are committed to Manufacturing & Supply of Pressure Vessels, Oil & Gas Piping's, Tanks and crystallizers for customized product mfg. company to achieve "Delightment" of all Stakeholders.

We shall achieve this by:

- Marching towards Zero defects in every activity of the organization

- Providing products and services which exceed customer expectations

- Training to our employees for continual improvement